SOLKAV ICE ROLL SS

The “grid-based flexible pipe” instead of concrete

ICE | ICE RINKS

Ice in the Stainless steel Ice roll

Connection of the STAINLESS STEEL ICE ROLL pipe system to the collector.

The HDPE collector system is installed mainly along the short side of the ice field and is connected to a refrigeration unit with a hydraulic module. A water shut-off valve is installed on each pipe, which allows you to instantly shut off the circuit in case of an emergency.

The collector pipe is not included in the delivery package, because supplied together with common pipes. For aesthetics reasons, the fittings are welded into the collector pipe directly at the work site.

Dimensional and weight parameters of the STAINLESS STEEL ICE ROLL system:

The weight of 1 sq.m of the ICE ROLL SS® ice rink pipe system is 3.0 kg (excluding manifold and fittings).

Diameter and weight of ICE ROLL SS® roll for ice field length:

• 40m – OD=90cm, weight 60kg

• 60m – OD=118mm, weight 90kg

The assembled

STAINLESS STEEL ICE ROLL ice rink pipe system set 30x60m consists of 60 rolls with a width of 55cm and a diameter of 118cm and fits completely into one standard Euro truck with a body length of 13.6m.

Total volume:

20 pallets measuring 120x120cm, height 185cm (3pcs. of ice rolls per pallet).

Total gross weight: 6300kg

VARIETY OF FORMS

Our STAINLESS STEEL ICE ROLL systems create projects not only established a distinctive entertainment area for residents and visitors of the city, but also highlighted an innovative method of constructing ice structures.

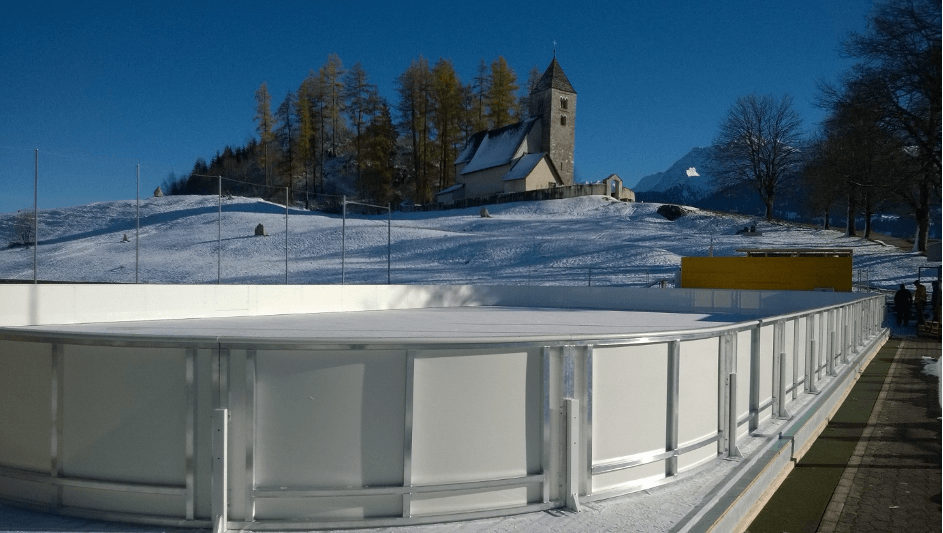

PERMANENT SKATING RINKS

STAINLESS STEEL ICE ROLL technology is used in the construction of Permanent Skating Rinks. Whether it's a training ground or an entertainment arena, you will get the required quality of ice at much lower costs and minimal installation time. The speed of installation during the construction of permanent facility allows you to save not only on the construction of the ice surface, but also on installing related systems, reducing the construction time of the entire facility.

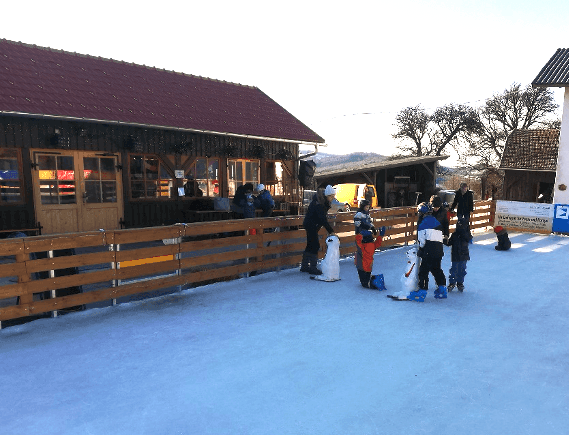

MOBILE ICE RINKS

STAINLESS STEEL ICE ROLL technology presents a versatile solution for creating mobile ice rinks of any size and layout, making it suitable for a wide range of applications such as constructing temporary seasonal skating rinks, hosting thrilling ice shows, and sculpting impressive ice slides and vertical ice surfaces. They can be effortlessly set up on any level surface within a brief timeframe, requiring minimal expertise for both installation and dismantling. Furthermore, the mobile ice fields boast easy storage and transportation capabilities, adding to their convenience and practicality.

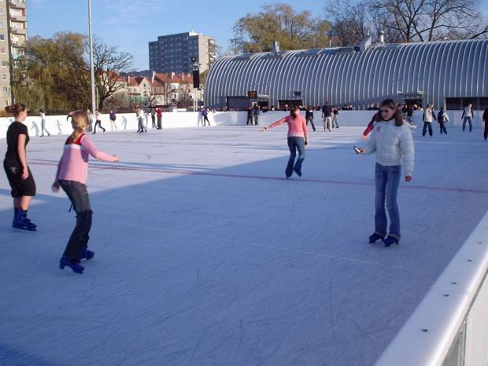

MULTIFUNCTIONAL AREA

STAINLESS STEEL ICE ROLL technology is used in the construction of multifunctional area; they can be used to host a wide variety of sports and entertainment events at different times of the year.

The pipe system can be filled with sand and granite chips or artificial grass can be laid on top. It is also possible to apply a hard quartz-polymer coating over the pipe system. In winter, the area is used as an ice skating rink, in summer - as place for football, basketball, volleyball, tennis, or just a rigid public area (in the case of a quartz-polymer coating).