SOLKAV Padding board

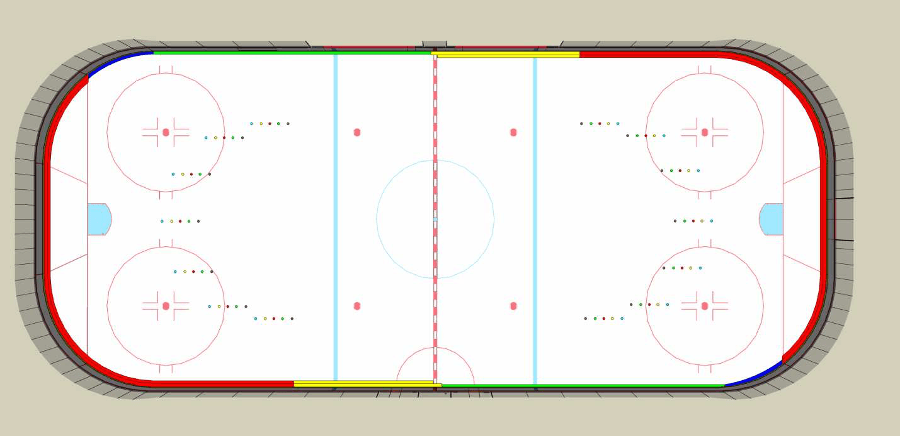

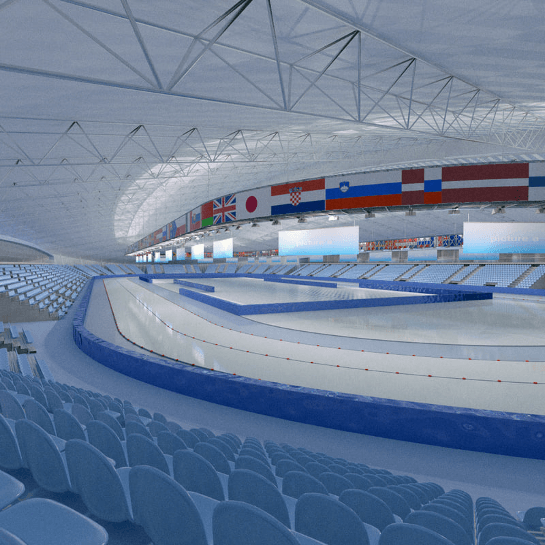

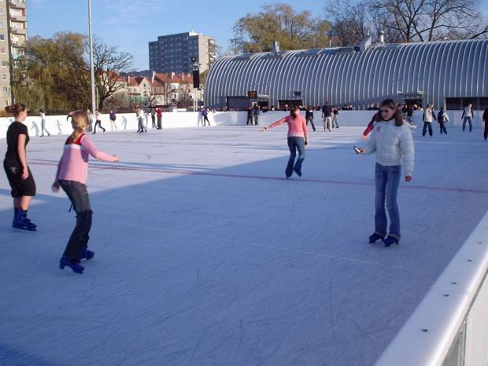

Speed skating | Short Track

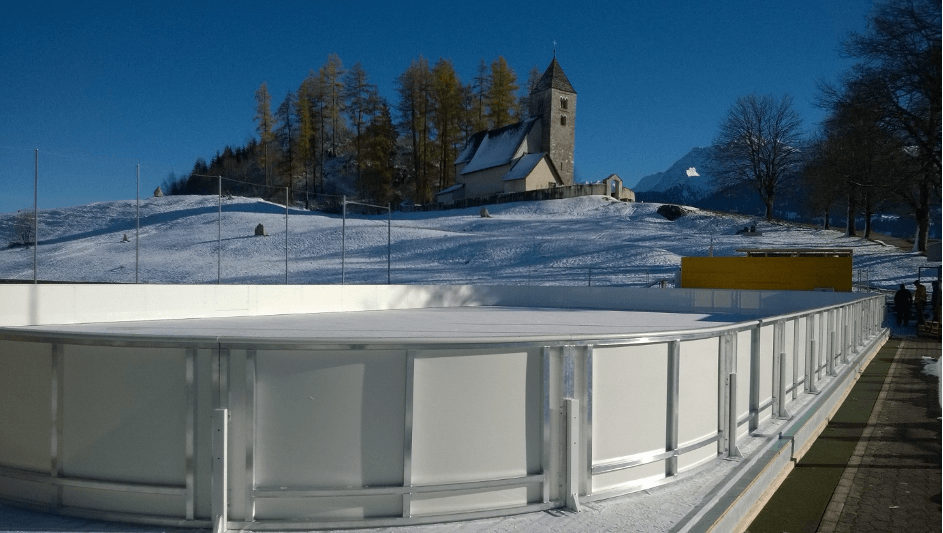

ICE | ICE RINKS

Speed Ice Skating Soft-Board

Concept

the padding boards

Foam bands for

Air boards for

Foam boards

The foam bands for short track and speed skating are built according to the specifications of the International Skating Union (ISU STANDARD). In terms of size and shape, to meet the needs of protection, to ensure high safety for the athletes, a soft impact and the almost total reduction of the dangerous rebound effect.

The foam rinks are suitable for use in combination with traditional ice hockey rinks by laying them directly on the ice and leaning against the PE rink. The same radius and the self-retaining connection of the panels result in a stable, self-supporting safety structure.

Protection system

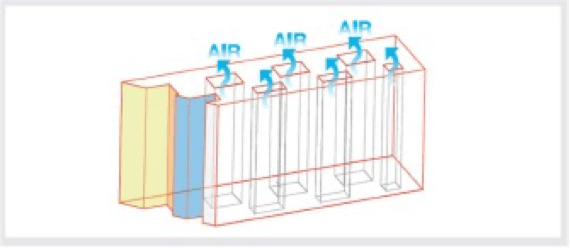

The protection systems work with special openings by using a synthetic mesh. The surfaces of the net are dimensioned to exude the restrained air at the inside of the protections with a precise relation between speed and time of evacuation. In order to make the use of the protective devices possible for outdoor locations as well, the net can be covered with a special membrane that allows air to escape and prevents water from entering. The excellent results of the protections are achieved with a special internal structure made of different layers of foam. The front part consists of a special slow-acting shock absorber, able to absorb the first phase and speed of the impact, avoiding a heavy impact for the athlete.

The other components of the protections are made with different layers of foam with different densities and open cell structure. This open cell structure guarantees the right ratio between air volume and foam mass, mandatory for correct cushioning and reducing the speed of the colliding athlete. The foams are specifically selected for their compression factors and deformations, which require a limited amount of compression at the time of impact, evacuating the air through the appropriate O-Pen-A channels. Each individual system has different internal structures that have been specially tested and tested to achieve the highest possible impact power and rebound reduction. The inner part of the mat consists of several types of foam that have different thicknesses and shapes.

The system is easy to install and dismantle.

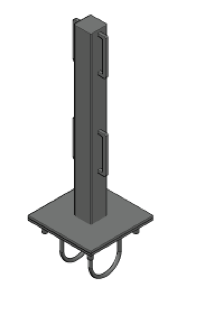

Post system

In areas where there is no PE boarding and the system needs to be self-supporting. Posts are installed and fixed into the back flap of the pad panel.

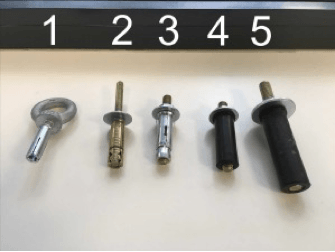

The bottom part of the feet can be flat to be bolted down or embedded in the concrete with anchors.

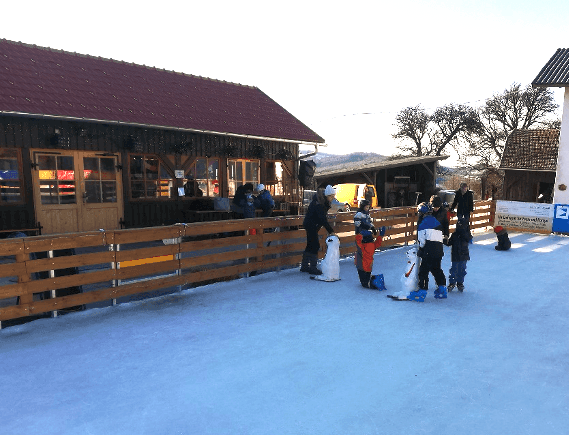

Air boarding

The airboarding is made with a high quality, high performance Panama 900 gr/m2 sheet in a color of your choice. The lower part is made with an I-Cetex protection to prevent wear on the lower part due to friction of the boarding system. For front protection, a cut resistant sheet metal is provided to ensure cut protection for the airboarding system. Both the airboarding and the fender are provided with Velcro on the top and bottom to mount advertising banners. The dimensions of the air cushions are 60 centimeters wide, 100 centimeters high. The air cushion system is built according to ISA Sport standards.

Characteristics

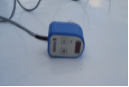

Pressure regulating installation

The system works with air inflation by blowers. The fan, the electronic pressure regulator and the inverter regulator (each 6 pieces) are around 400 mtr. Protective board side placed under the floor. A visual controller is installed in your technical room. The controller is connected to the inverter controller and the pressure controller via steering cables.

You can control from everywhere (controller, PC, Handheld) via internet. In the case that a tear will appear as a result of a skater falling into the boarding, the PLC will communicate this immediately to the fans, and the fans will ensure an adjusted airflow, so that the pressure will be on the right level again and will be maintained at this level.

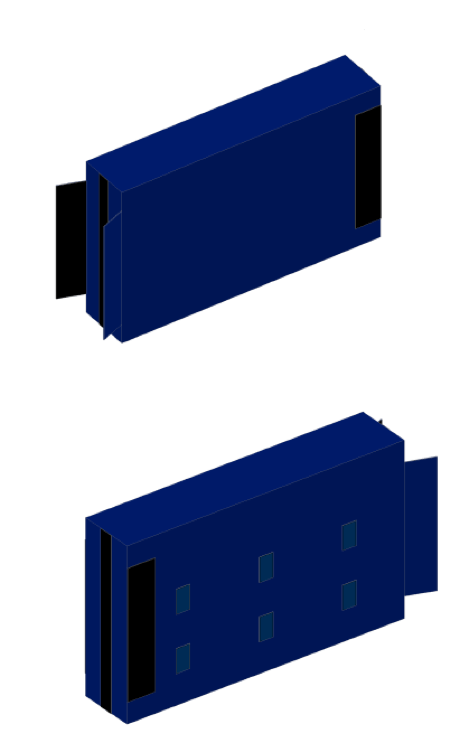

Fixation and storage

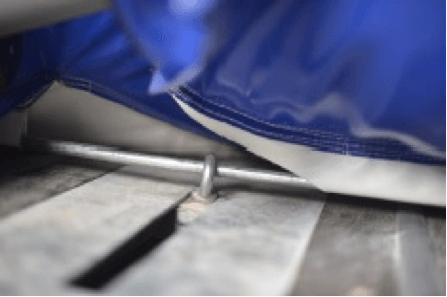

The air cushion is free-standing and very easy to dismantle. The attachment to the ground will keep the airboarding in place and therefore no additional fencing will be necessary. This is a great advantage when the surface of the ice ink is used for other purposes. Dismantled storage means letting the air out and storing just a lot less than foam panels (minus 75%).

The bottom side of the boarding is made of Icetex 2.0 and all the doors and passages are equipped with wear resistant covers. All the seams on the ice side are welded, the inner work is reinforced, the ends of the boarding are made heavier, the doors are equipped with handgrips which are welded and sewed, every part is marked on a fixed position.

On the front there is a sheet of Icetex 2.0, which is attached to the door with Velcro. An extra strong layer is attached between the 2 layers of Icetex 2.0 so that the skate cannot go through the blade and the boarding is not perforated. Velcro is also sewn on the ice side so that the banners can be attached directly to the side of the board. The air barrier covers the straight parts about 82 meters long on each side of the ice rink. Segments will be about 20 meters each and will be fitted with door parts, photo finish ready and a driving gate for the Ice machine if needed. All parts will be made according to the technical drawing, delivered with supply.

Both the airboarding and the protection sheet will be provided with velcro on the top and bottom for the purpose of mounting commercial banners.

Post System

The airboarding will be anchored to the concrete floor with special anchoring, which means in the riskzones (the critical parts in and direct after the corners) the anchoring will slide back thanks to a special rail/spring construction, therefore the bounce back will be reduced and the impact capacity will be increased.

This sliding system has to be placed into the ground every 75 cm within the risk zone.

For the placement of this system a hole has to be milled into the floor to fit the sliding boxes, these boxes have a dimension of 52x22x4.5cm (LxHxW).

Afterwards the holes in the floor have to be filled with concrete again to ensure a tightened system.

Anchors can be flat to be unscrewable and are embedded in asphalt or in concrete.