The SOLKAV Ice hall technology

IIHF and Olympic standard

ICE | ICE HALLS

Complete system

1. Ice field technique

Ice fields for Olympic sizes of 30 x 60 or in minimum of 26 x 56 for Ice Hockey are usually done by PE/PP piping on iron grid fixed and filled with concrete.

Solkav does 3 things superior

1.

We use endless FLEX tubes that allow a tight radius. (Solkav Ice Plast). With this we avoid bad flow in the ice field caused by bad welding. "the zebra apparition".

2.

We use 5 cm distance between the pipes to ensures same temperature everywhere on the ice field and to save energy by having 1-5°C (5%) less temperature / electricity consumption

3.

We use concrete of best quality (inside C30; outside C35), with high elasticity to avoid cracks in the surface.

For 12 months installation we recommend to avoid

“Perma frost” installations (meaning to fill the gap between the pipe/iron grid with wet sand) but to use our Cassette system with Ice Plast

The refrigeration technology can always be implemented in 3 variants

1.

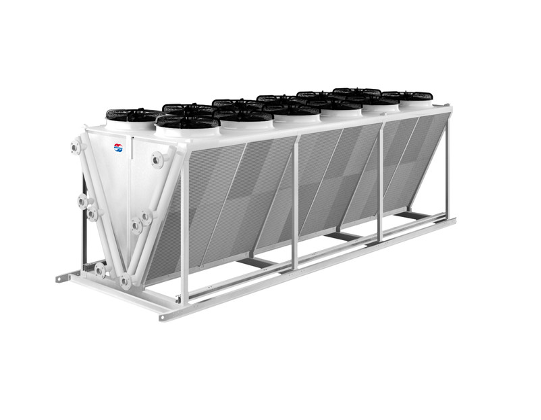

as a refrigeration combination station for outdoor installation

2.

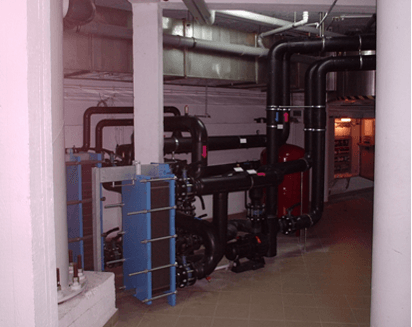

Optional as a split device (compressor technology in the machine room and with dry cooler outdoors)

3.

Optional as a split device (compressor technology in the machine room with water tower)

Variants

The choice of the unit combination depends on the one hand on whether an outdoor installation is possible (simplest version) and what noise level is permissible. The water cooler version is by far the quietest version (in terms of price-performance ratio).

Solkav builds the refrigeration technology either as an ice rink cooling system or as a central cooling station for the ice rink and the dehumidification system. This has the advantage of an overall smaller unit and significant cost savings compared to two cooling systems.

This then makes the "continuation" to a comprehensive heat recovery system (Green Package) really useful!

3. With Green (Heat Recuperation) package on Demand

The waste heat at the level of 25°C can also be increased to 80°C with a Hucke Pack heat pump; and with relatively little use of energy.

This results in usable heat at a temperature level of 80° C: 350 KW

The ice rink, although an "energy destroyer par excellence", can become one "Green ice rink" can be expanded, which does not require any further fossil fuels.

The refrigeration technology supplies the used KW cold + the use of electrical energy as waste heat in a single stage with an additional water condenser at a temperature level of 25° C to 25° C in an "economical" range. About 10% of this can be obtained at a maximum temperature of 65°C. In a well dehumidified system with correct internal temperatures (15° C hall temperature; 8° C 1m above ice) these are approximately:

Thus, when fully expanded, the entire heat requirement can be supplied

4. Dehumidification technique

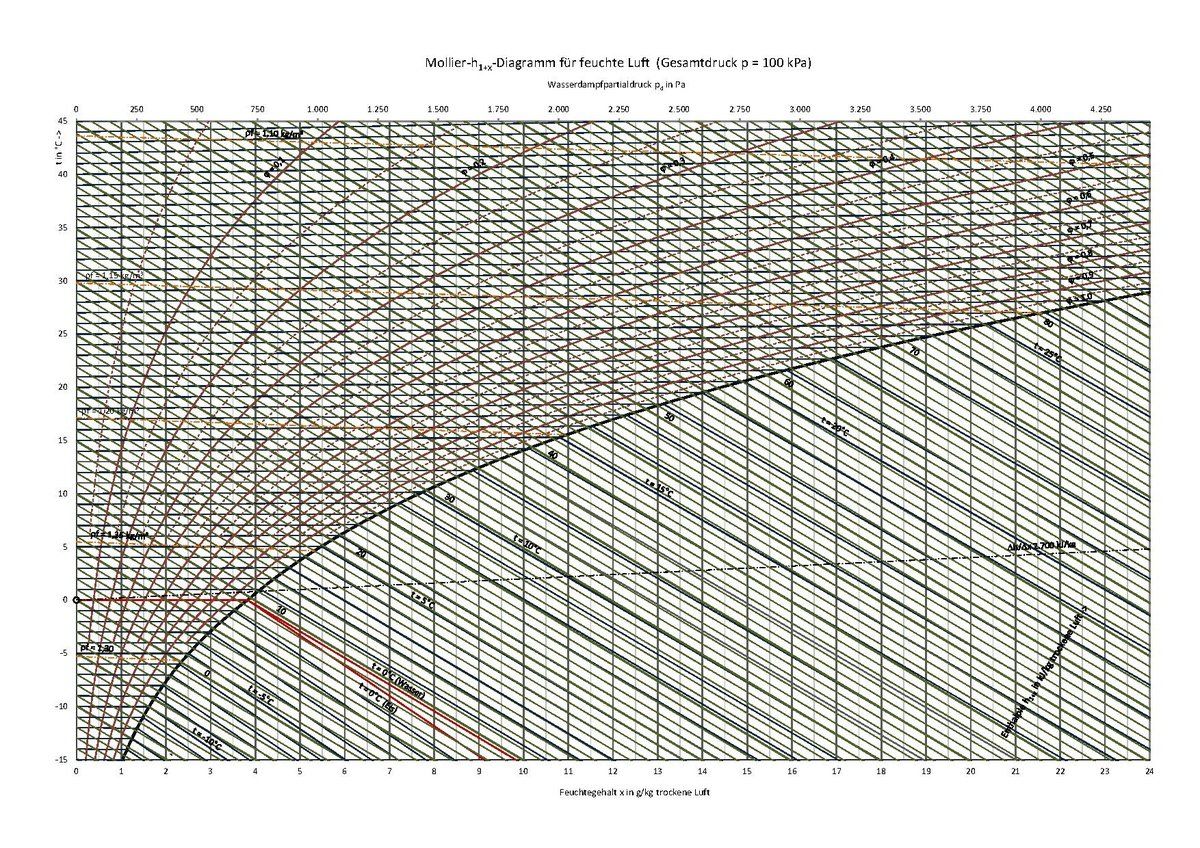

The ice rink air must be dehumidified to a maximum level of 55% relative humidity. At the same time, the air temperature in the ice rink should be: 8° C at a height of 1 m within the ice barrier and 15° C at the middle height of the room. This can be guaranteed with a cold-based dehumidification system under winter/spring conditions.

When operating at outside temperatures above 25° C, pure cold dehumidification is no longer sufficient, since the dehumidified air that can be blown in can no longer absorb the humidity of the outside air. A 2-stage dehumidification with cold and heating cooling must then be used.

For single-stage cooling with cold, the central refrigeration system provides the cold. The piggyback heat pump produces the reheating to room inlet temperature.

With 2-stage dehumidification, the central cold produces the dehumidification cold and the cold for cooling the air after the heating process. The heat supply is then limited to the drying heat of the air. In both cases, with a piggyback heat pump, there is no need for third-party additional heating. The dehumidification system is your air conditioning and heating system at the same time

It is your

central system for indoor climate and compliance with ice conditions! And a major operating cost factor. What you initially invest in heat recovery, you save very quickly in the operation of your dehumidification/cooling and heating system.

In case no gas heating for “Heat Dehumidification” available, we use electrical heaters or our Green Booster to bring up via Heat pump the waste heat to usable level.

IIHF standard boards for ice hockey, must be stable and still attractive.

Solkav offers the gang in a modular form:

Basic package

Premium Upgrade

Kickboard technology with full glazing without a stand

The upgrade includes 2 extensions