SOLKAV MAIN CONTACT | 43 2743 20150 | Walter Kirnich | 43 699 171 52 725 | Mail: office@solkav.eu

SOLKAV ALU STAR

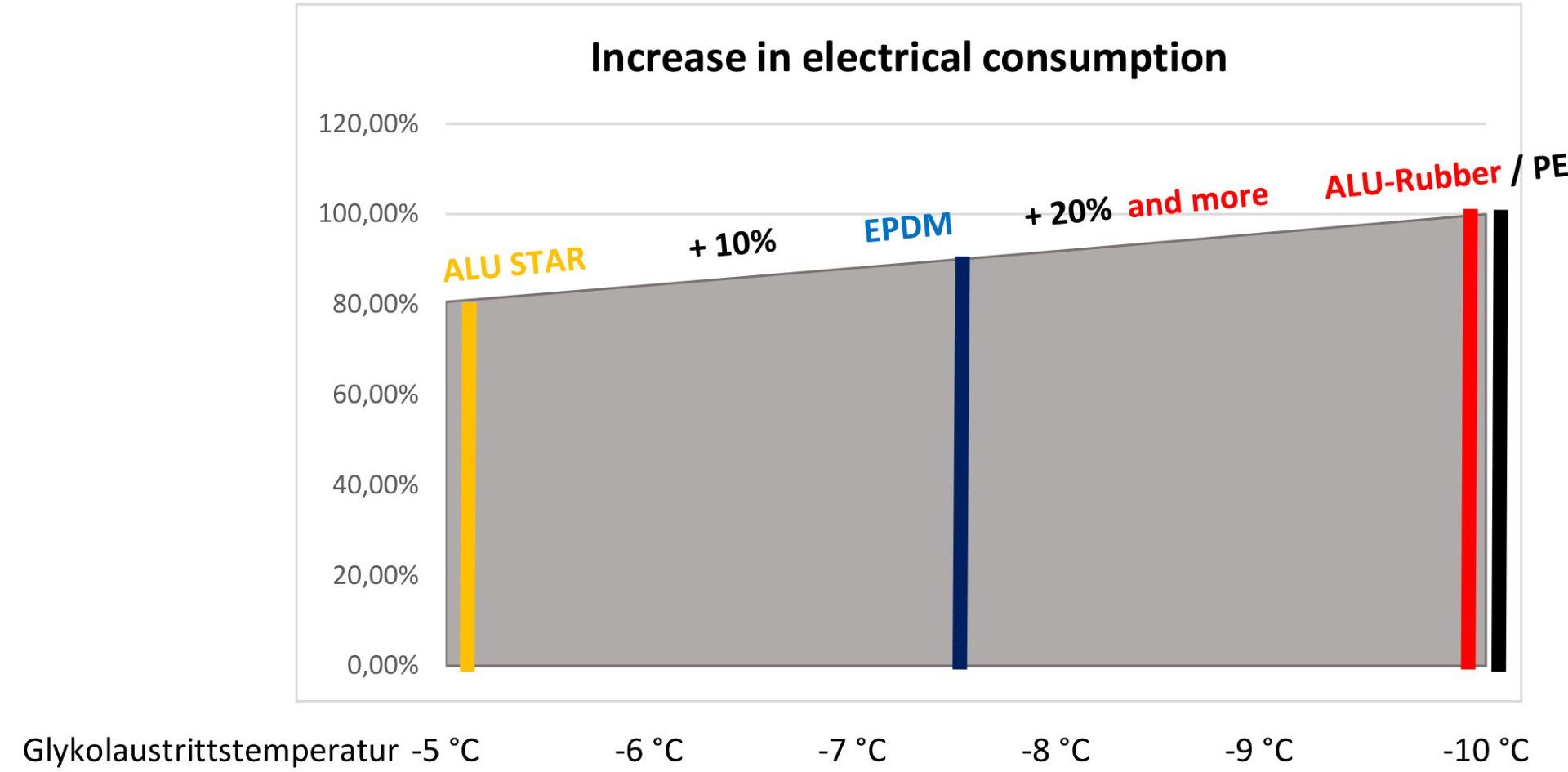

The “electricity safer” and more

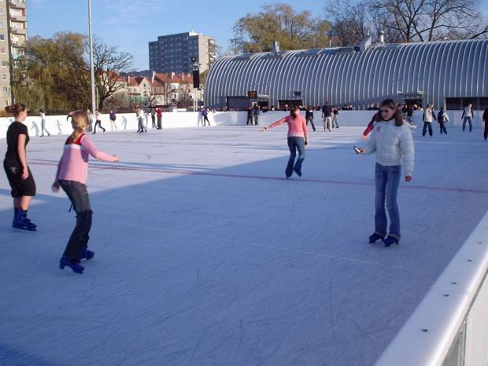

EIS | ICE RINKS

ALU STAR

A continuous aluminum ice field guarantees minimal electrical power consumption:

-5°C glycol outlet is sufficient where others require -10°C >>> - 20% of electrical power

3 tube header system guarantees consistent ice quality across the field

3 tube header system guarantees consistent ice quality across the field

The Best ice quality!

ALU STAR withstands: warm wind, more sun, higher temperatures better than any other system. By far!

Why? Very simple: You have 5 K more potential to freeze | Individual Design: Single panels of 5m or individual length let you decide each year your design: e.g. 15 x 30; 20 x 20, 12 x 35 | Long term product quality – All connections WELDED | The proof: First systems from 10 years ago still in use

Minimal electrical power consumption

The Solkav ALU STAR is designed to save energy and costs. We compare the 4 ice field types commonly used as a mobile system

Full Aluminium, Typos Solkav ALU STAR, 3- Pipe Header system

ALU- Rubber ice fields, 2 Pipe Header system

EPDM Ice fields, 3- Pipe Header system

EPDM Connect: extension tracks for up to 100m PE ice rinks, 2-pipe header system

The different electricity consumption has 4 reasons

1.

Flexible, non-metallic material requires between 2 K (EPDM) and 3 to 4 K (PE ice rinks and hose connections between aluminum pipes) lower evaporation temperatures. Each Kelvin costs about 4% electricity.

2.

Pipe header systems generate different ice field temperatures from the glycol inlet to the end of the header of 0.5 - 1K which the chiller has to compensate for.

3.

With ALU-rubber ice fields, the effect is observed that the ice on the opposite side of the header is worse. The reason is flow problems with the rubber hose connections, this effect costs around 0.5 to 1 K.

4.

Aluminum, ALU-Rubber and PE ice fields require less pump power due to larger pipe diameter (about 3% electricity). In the case of mobile systems, either the pump current is reduced or, if the pump is not smaller, the temperature difference between the inlet and outlet is reduced and the evaporation temperature required as a result. (0.5 to 1K).

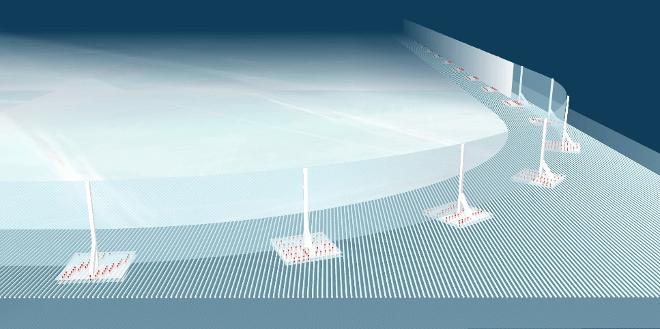

Best ice quality

ALU Star consists of ALU panels measuring 1m x 5m, with 20 tubes OD 20 mm. That means a pipe spacing of 5cm between the middle and middle. The panel length can be chosen between 0.5m and max. 6m. The standard panel is 5m. So for a 15 x 30 m ice rink you need 90 panels with 5 m. These panels are connected with screws. Directly!!! There are no connectors in between. (Inside the ice field). This means there are no flow disturbances. The metal's conductivity of 0.000xxx can be fully utilized.

Under winter conditions a glycol outlet temperature of -5°C is fine. So you have still for periods of warm wind, strong sun, high outside temperatures a reserve of 7K. Usual limit of standard Chillers.

In reality, the ALU STAR ice field is still alive while ice fields made of other materials are already dead. The best product for late winter installations, hot areas and other poor conditions.

Warm wind, much sun, high temperature ALU STAR withstands

better than any other system. BY FAR:

Why? Very simple: You have 5 K more potential to freeze

Individual Design

The design of single panels makes it easy to change size of the ice rink you install. You can vary between length and width.

The panels are stored in storage boxes; you get delivered a kit, ready to install, dismantle, and store again. In case you want to enlarge your Ice Rink, you just buy further modules (Panels, headers, etc.) and enlarge. We also manufacture custom systems; e.g. for ice rinks with mobile feet or curved panels.